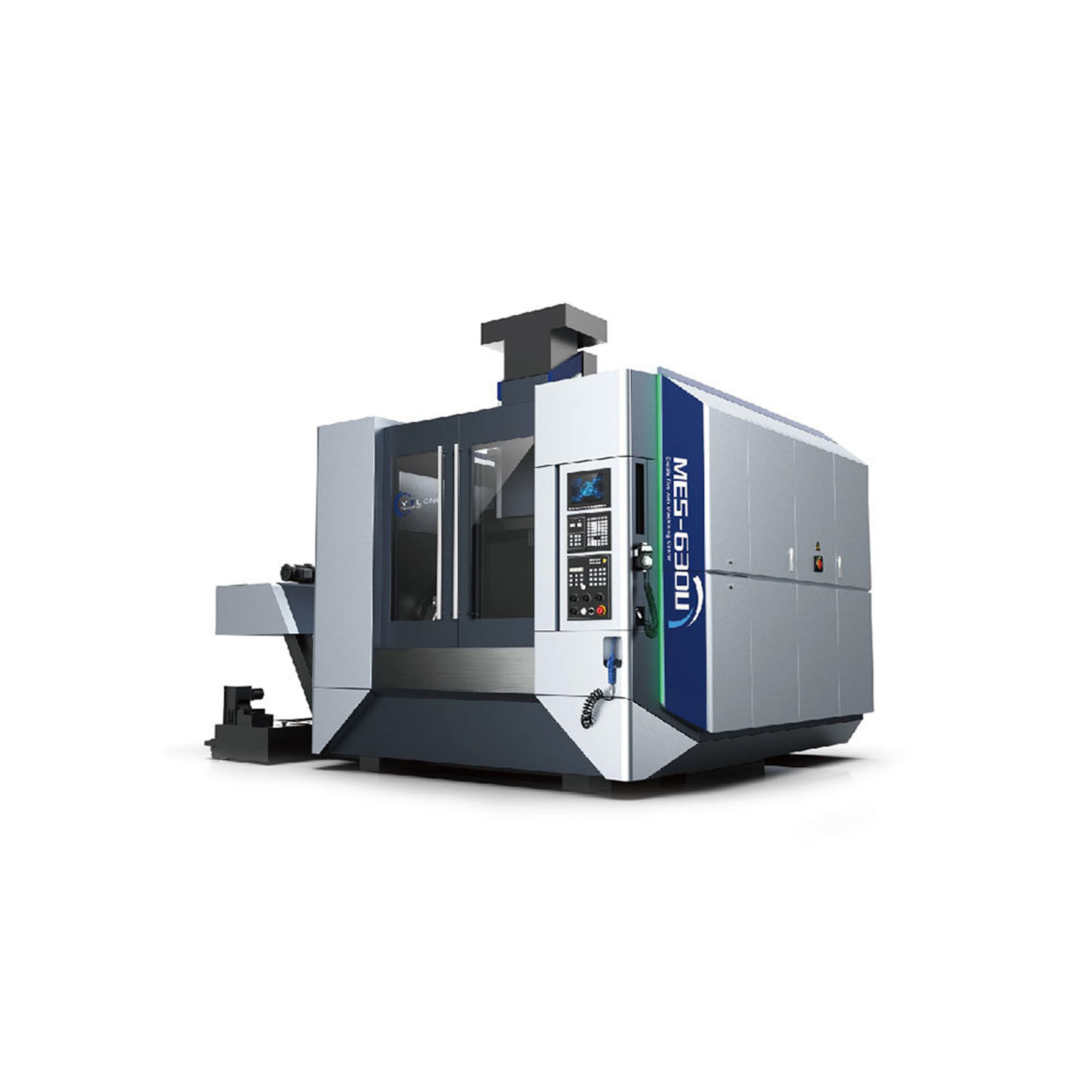

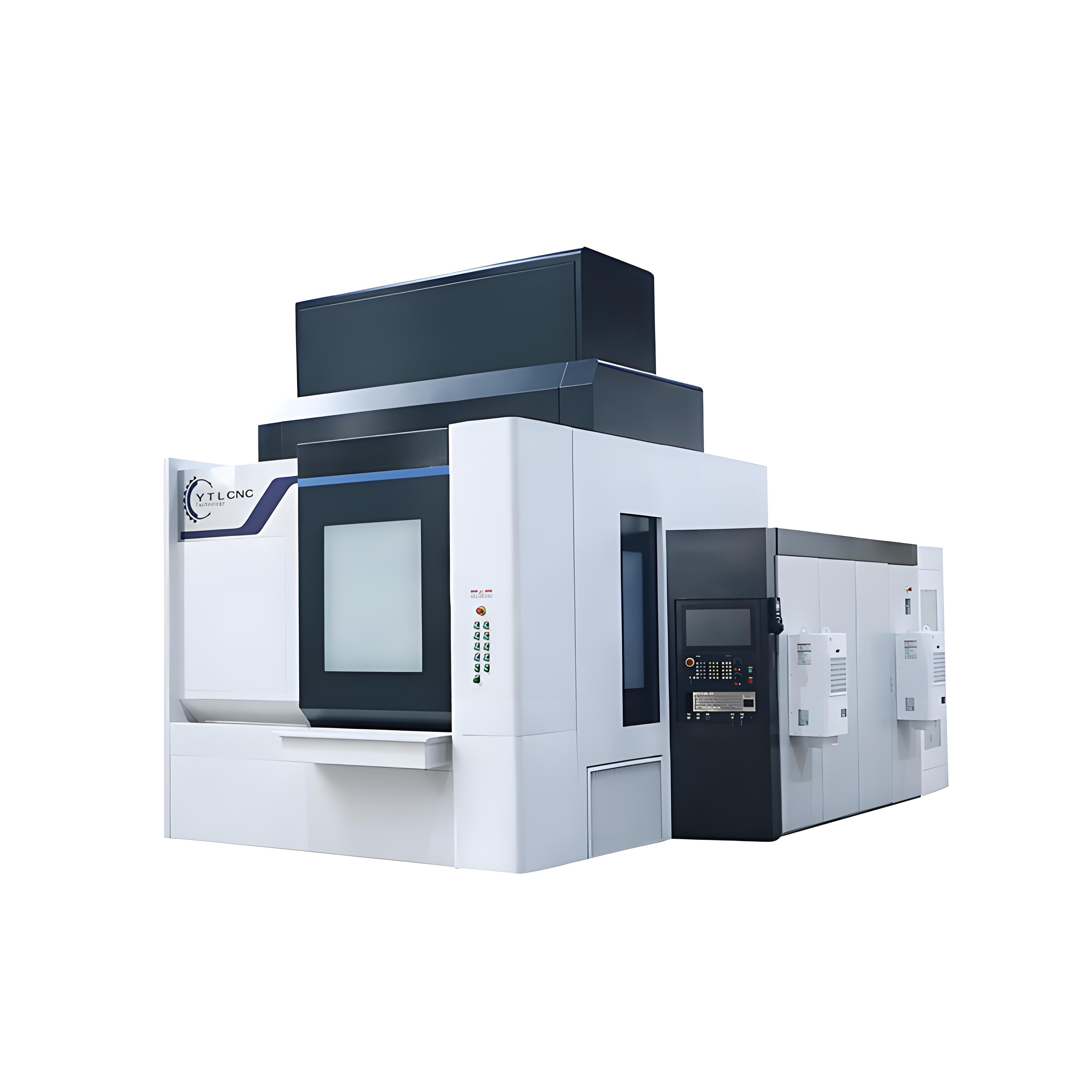

GRANDE high-speed composite five-axis gantry machining center

Retail Price

Market price

Supplier:

Weight

Stock surplus

隐藏域元素占位

- Product Description

- Product specifications and models

-

- Brand: YTLCNC

- Commodity name: GRANDE high-speed composite five-axis gantry machining center

The GRANDE series is a large gantry machining center specifically designed by Italy for the composite materials industry. It can process oversized wind turbine blades, models, aircraft structural components, etc., all at once. With its patented dual-beam technology and unique box-in-box structure, it offers unique advantages in processing large workpieces.

Existing wind power industry users have large-scale equipment with a processing range of 40m on the X-axis, 8m on the Y-axis, and 4.5m on the Z-axis in stable operation.

Application Areas: Wind power, aerospace

Examples: Wind turbine blades, large models, wings, fuselage, aerospace structural components

Applicable Processing Materials: Carbon fiber, fiberglass, aramid honeycomb, aluminum honeycomb, foam, honeycomb panels, substitute wood, and other composite materials -

GRANDE Series GRANDE 25 Series GRANDE 30 Series GRANDE Series Five-axis head HS03/HS04/HS13/HS15 HS03/HS04/HS13/HS15 HS03/HS04/HS13/HS15 X-axis travel 4000/6000/8000 4000/6000/8000 4000/6000/8000…60000 Y-axis travel 2500 3000 3500…8000 Z-axis travel 1500 1500 1500…4500 A-axis rotation range ±110/±120 ±110/±120 ±110/±120 C-axis rotation range ±360(±270) ±360(±270) ±360(±270) Gantry overhang 3700 4200 4200…9200 Spindle vertical to worktable 50-1550 50-1550 50-1550…4550 Worktable length (optional) 4000/6000/8000 4000/6000/8000 4000/6000/8000…60000 Worktable width (optional) 2500 3000 3500…8000 Maximum worktable load (optional) 3 3 3 T-slot (width*pitch) (optional) 22*250 22*250 22*250 X/Y/Z-axis rapid traverse speed 50/50/30(25) 50/50/30(25) 50/50/30(25) X/Y/Z-axis maximum feed rate 20/20/20 20/20/20 20/20/20 A/C-axis rapid traverse speed 40/40 (20/20) 40/40 (20/20) 40/40 (20/20) A/C-axis maximum feed rate 20/20 20/20 20/20 Floor space length 2010/12/14 2010/12/14 10/12/14……66 Floor space width 7.5 8.4 8.9……13.4

Previous Page

Product specifications and models

| GRANDE Series | GRANDE 25 Series | GRANDE 30 Series | GRANDE Series |

| Five-axis head | HS03/HS04/HS13/HS15 | HS03/HS04/HS13/HS15 | HS03/HS04/HS13/HS15 |

| X-axis travel | 4000/6000/8000 | 4000/6000/8000 | 4000/6000/8000…60000 |

| Y-axis travel | 2500 | 3000 | 3500…8000 |

| Z-axis travel | 1500 | 1500 | 1500…4500 |

| A-axis rotation range | ±110/±120 | ±110/±120 | ±110/±120 |

| C-axis rotation range | ±360(±270) | ±360(±270) | ±360(±270) |

| Gantry overhang | 3700 | 4200 | 4200…9200 |

| Spindle vertical to worktable | 50-1550 | 50-1550 | 50-1550…4550 |

| Worktable length (optional) | 4000/6000/8000 | 4000/6000/8000 | 4000/6000/8000…60000 |

| Worktable width (optional) | 2500 | 3000 | 3500…8000 |

| Maximum worktable load (optional) | 3 | 3 | 3 |

| T-slot (width*pitch) (optional) | 22*250 | 22*250 | 22*250 |

| X/Y/Z-axis rapid traverse speed | 50/50/30(25) | 50/50/30(25) | 50/50/30(25) |

| X/Y/Z-axis maximum feed rate | 20/20/20 | 20/20/20 | 20/20/20 |

| A/C-axis rapid traverse speed | 40/40 (20/20) | 40/40 (20/20) | 40/40 (20/20) |

| A/C-axis maximum feed rate | 20/20 | 20/20 | 20/20 |

| Floor space length | 2010/12/14 | 2010/12/14 | 10/12/14……66 |

| Floor space width | 7.5 | 8.4 | 8.9……13.4 |

Product Introduction

The GRANDE series is a large gantry machining center specifically designed by Italy for the composite materials industry. It can process oversized wind turbine blades, models, aircraft structural components, etc., all at once. With its patented dual-beam technology and unique box-in-box structure, it offers unique advantages in processing large workpieces.

Existing wind power industry users have large-scale equipment with a processing range of 40m on the X-axis, 8m on the Y-axis, and 4.5m on the Z-axis in stable operation.

Application Areas: Wind power, aerospace

Examples: Wind turbine blades, large models, wings, fuselage, aerospace structural components

Applicable Processing Materials: Carbon fiber, fiberglass, aramid honeycomb, aluminum honeycomb, foam, honeycomb panels, substitute wood, and other composite materials

PDF Product Catalog

Exhibition Hall

The seller will attend the following exhibitions