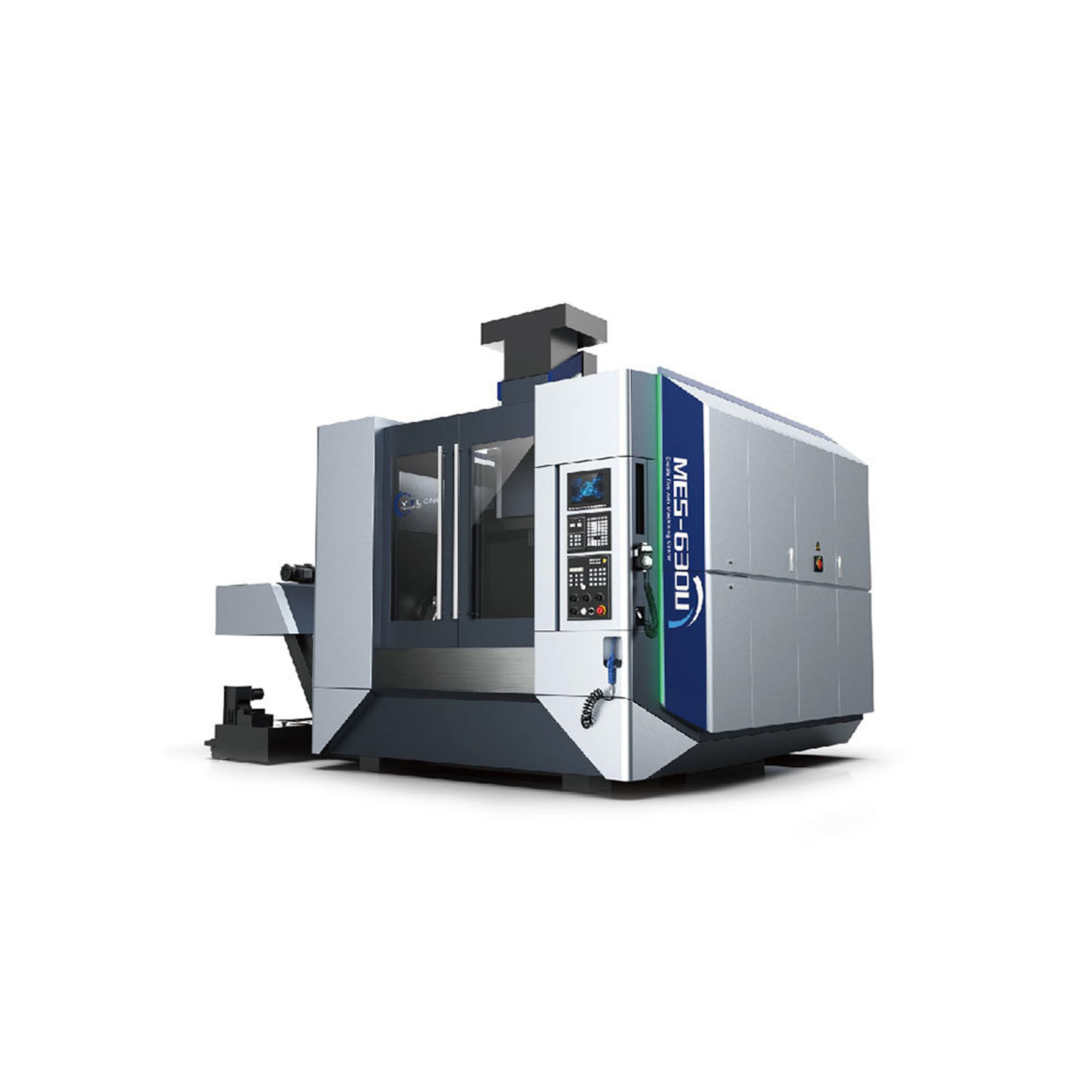

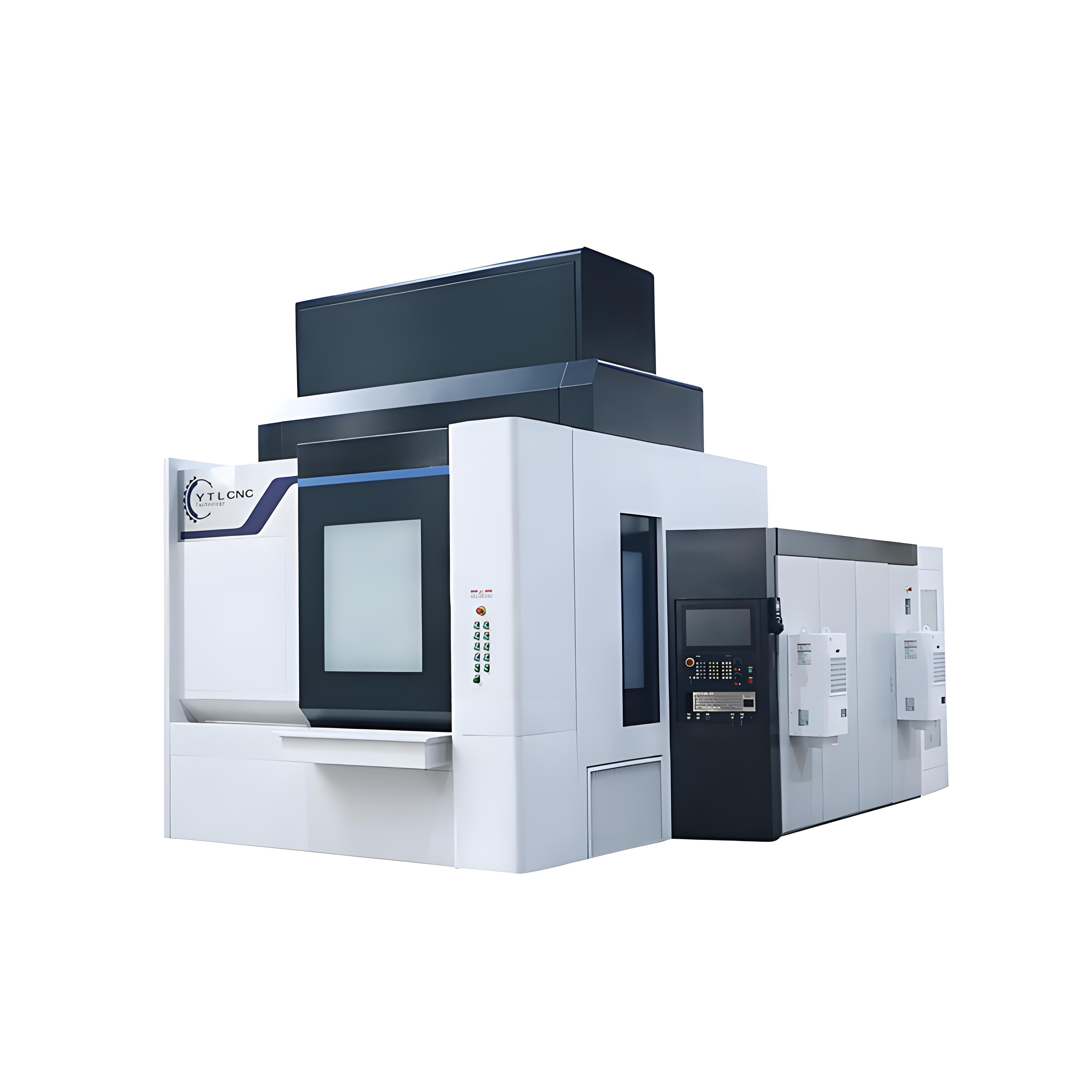

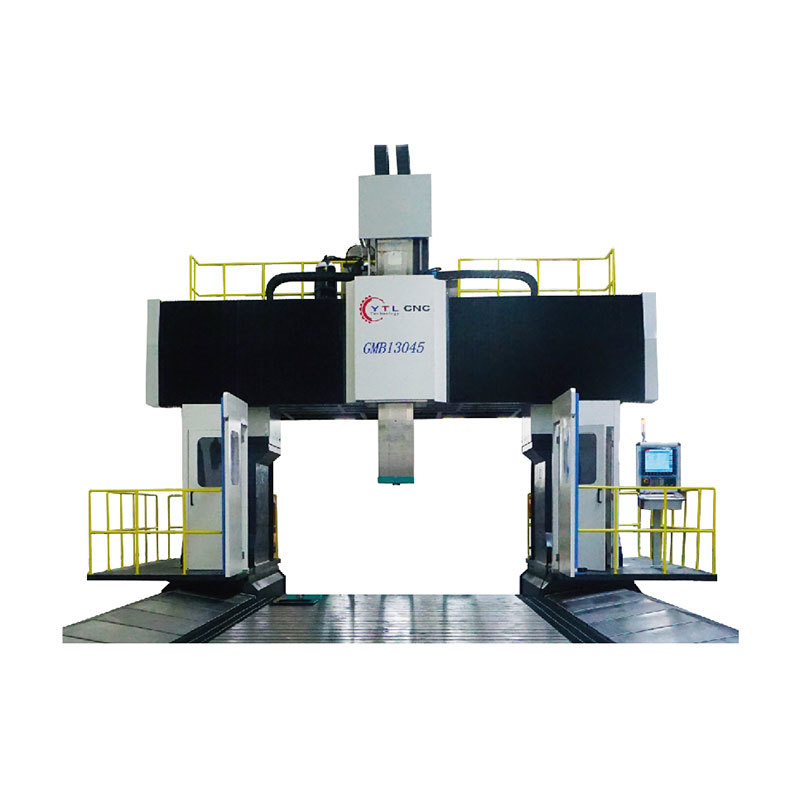

PROFILE six-axis gantry machining center

Retail Price

Market price

Supplier:

Weight

Stock surplus

隐藏域元素占位

- Product Description

- Product specifications and models

-

- Brand: YTLCNC

- Commodity name: PROFILE six-axis gantry machining center

The six-axis long-beam machining center, as a special model used by Italy for flexible machining of important longitudinal components of modern aircraft fuselage structures—long beams and girders, uses five-axis linkage machining combined with flexible robot clamping to achieve efficient and high-precision one-time clamping and completion of machining, greatly improving machining efficiency.

Application fields: aerospace, rail transit

eg: stringers, etc., as longitudinal components of the fuselage structure

Applicable processing materials: aluminum alloy, steel, aluminum skin, carbon fiber, etc.

-

PROFILE Series Unit PROFILE Series PROFILE Series Number of Axes 5+1 5+1 X-axis travel mm 3000-80000 3000-80000 Y-axis travel mm 1600-6000 1600-6000 Z-axis travel mm 1000 1500 A-axis rotation range ° ±110 ±110 C-axis rotation range ° ±360(±270) ±360(±270) T-slot width mm 36 36 Maximum table load T/㎡ 1 1 X-axis rapid traverse speed m/min 40(60) 40(60) Y-axis rapid traverse speed m/min 40(60) 40(60) Z-axis rapid traverse speed m/min 25(40) 25(40) Maximum X-axis feed rate m/min 30 30 Maximum Y-axis feed rate m/min 30 30 Maximum Z-axis feed rate m/min 20 20

Previous Page

Product specifications and models

| PROFILE Series | Unit | PROFILE Series | PROFILE Series |

| Number of Axes | 5+1 | 5+1 | |

| X-axis travel | mm | 3000-80000 | 3000-80000 |

| Y-axis travel | mm | 1600-6000 | 1600-6000 |

| Z-axis travel | mm | 1000 | 1500 |

| A-axis rotation range | ° | ±110 | ±110 |

| C-axis rotation range | ° | ±360(±270) | ±360(±270) |

| T-slot width | mm | 36 | 36 |

| Maximum table load | T/㎡ | 1 | 1 |

| X-axis rapid traverse speed | m/min | 40(60) | 40(60) |

| Y-axis rapid traverse speed | m/min | 40(60) | 40(60) |

| Z-axis rapid traverse speed | m/min | 25(40) | 25(40) |

| Maximum X-axis feed rate | m/min | 30 | 30 |

| Maximum Y-axis feed rate | m/min | 30 | 30 |

| Maximum Z-axis feed rate | m/min | 20 | 20 |

Product Introduction

The six-axis long-beam machining center, as a special model used by Italy for flexible machining of important longitudinal components of modern aircraft fuselage structures—long beams and girders, uses five-axis linkage machining combined with flexible robot clamping to achieve efficient and high-precision one-time clamping and completion of machining, greatly improving machining efficiency.

Application fields: aerospace, rail transit

eg: stringers, etc., as longitudinal components of the fuselage structure

Applicable processing materials: aluminum alloy, steel, aluminum skin, carbon fiber, etc.

PDF Product Catalog

Exhibition Hall

The seller will attend the following exhibitions