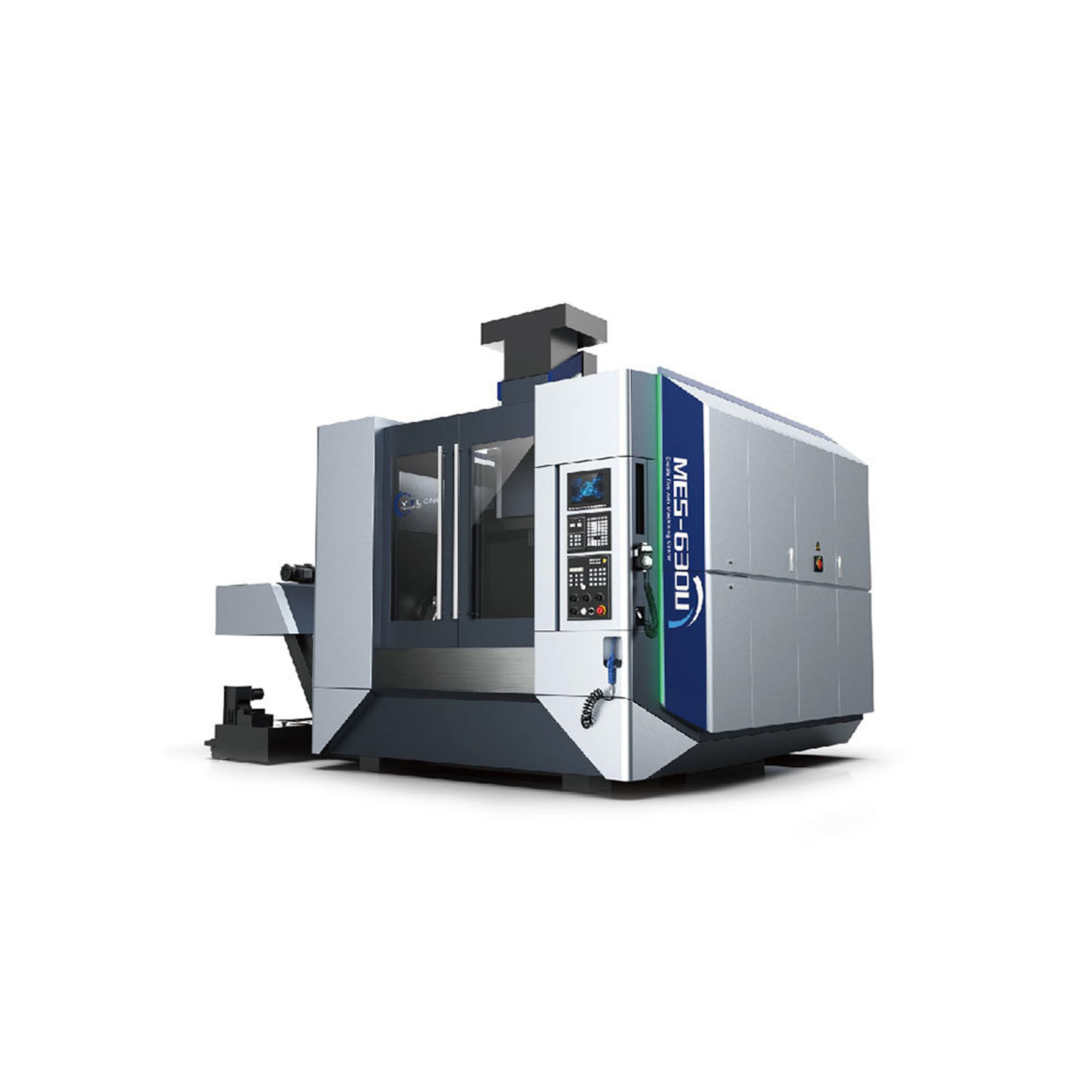

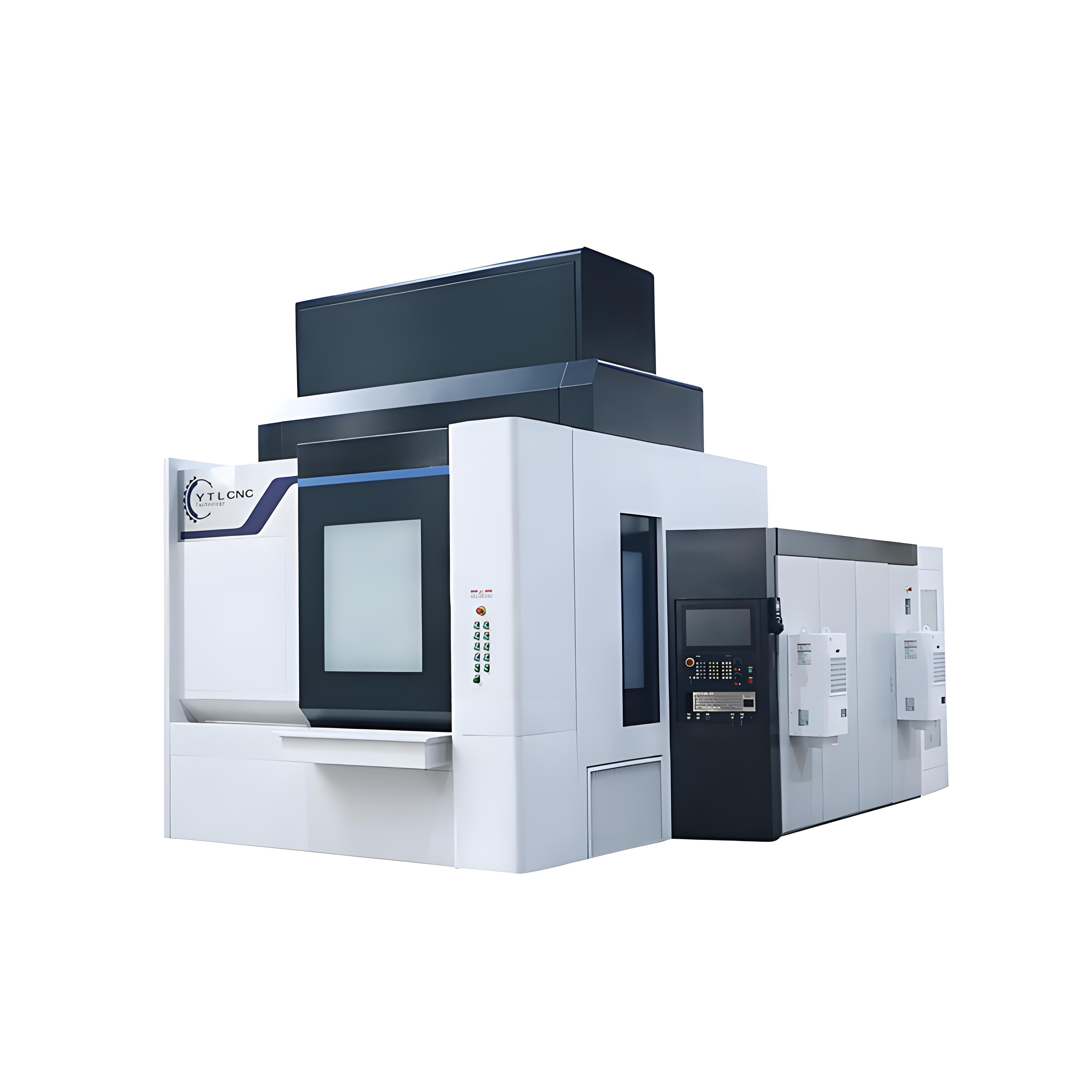

SAKER high-efficiency five-axis horizontal turning machining center

Retail Price

Market price

Supplier:

Weight

Stock surplus

隐藏域元素占位

- Product Description

- Product specifications and models

-

- Brand: YTLCNC

- Commodity name: SAKER high-efficiency five-axis horizontal turning machining center

SAKER high-efficiency five-axis horizontal pallet machining centers feature pioneering and high-performance milling spindles. They enable the efficient manufacturing of various materials in the aerospace industry. The automated system, standard as part of the configuration, and the newly developed pallet exchange performance are important components of the horizontal pallet machining center. The innovative mobile column design, rigid bed, and high-dynamic performance milling head ensure a highly efficient milling process.

Application Areas: Aerospace

eg: Large aircraft structural components, wings, fuselage, etc.

Suitable Processing Materials: Aluminum alloy, Titanium alloy

-

SAKER Series SAKER 3014 SAKER 4020 SAKER 5025 Number of Axes 9 9 9 X-axis travel 3000 4000 5000 Y-axis travel mm 1400 2000 2500 Z-axis travel mm 500/650 500/650 500/650 X/Y/Z-axis rapid traverse speed m/min 50/50/50 50/50/50 50/50/50 X/Y/Z-axis maximum feed rate m/min 40/40/40 40/40/40 40/40/40 Acceleration m/s² 5 5 5 AC head (optional mechanical head) HS01/HS02 HS01/HS02 HS01/HS02 Tray Length * Width mm 3000*1400 4000*2000 5000*2500 Tray load capacity T 4 4 4 Bolt holes M16(Standard) M16(Standard) M16(Standard) Bolt hole grid spacing mm 200*200 200*200 200*200 Tray automation Y1 lifting axis mm 2650 2750 2850 Z1 transverse feed axis mm 5750 5850 5950 Number of trays pc 1900/1/2 2 2 Tray exchange time min 4 2 4

Previous Page

Product specifications and models

| SAKER Series | SAKER 3014 | SAKER 4020 | SAKER 5025 |

| Number of Axes | 9 | 9 | 9 |

| X-axis travel | 3000 | 4000 | 5000 |

| Y-axis travel mm | 1400 | 2000 | 2500 |

| Z-axis travel mm | 500/650 | 500/650 | 500/650 |

| X/Y/Z-axis rapid traverse speed m/min | 50/50/50 | 50/50/50 | 50/50/50 |

| X/Y/Z-axis maximum feed rate m/min | 40/40/40 | 40/40/40 | 40/40/40 |

| Acceleration m/s² | 5 | 5 | 5 |

| AC head (optional mechanical head) | HS01/HS02 | HS01/HS02 | HS01/HS02 |

| Tray | |||

| Length * Width mm | 3000*1400 | 4000*2000 | 5000*2500 |

| Tray load capacity T | 4 | 4 | 4 |

| Bolt holes | M16(Standard) | M16(Standard) | M16(Standard) |

| Bolt hole grid spacing mm | 200*200 | 200*200 | 200*200 |

| Tray automation | |||

| Y1 lifting axis mm | 2650 | 2750 | 2850 |

| Z1 transverse feed axis mm | 5750 | 5850 | 5950 |

| Number of trays pc | 1900/1/2 | 2 | 2 |

| Tray exchange time min | 4 | 2 | 4 |

Product Introduction

SAKER high-efficiency five-axis horizontal pallet machining centers feature pioneering and high-performance milling spindles. They enable the efficient manufacturing of various materials in the aerospace industry. The automated system, standard as part of the configuration, and the newly developed pallet exchange performance are important components of the horizontal pallet machining center. The innovative mobile column design, rigid bed, and high-dynamic performance milling head ensure a highly efficient milling process.

Application Areas: Aerospace

eg: Large aircraft structural components, wings, fuselage, etc.

Suitable Processing Materials: Aluminum alloy, Titanium alloy

PDF Product Catalog

Exhibition Hall

The seller will attend the following exhibitions