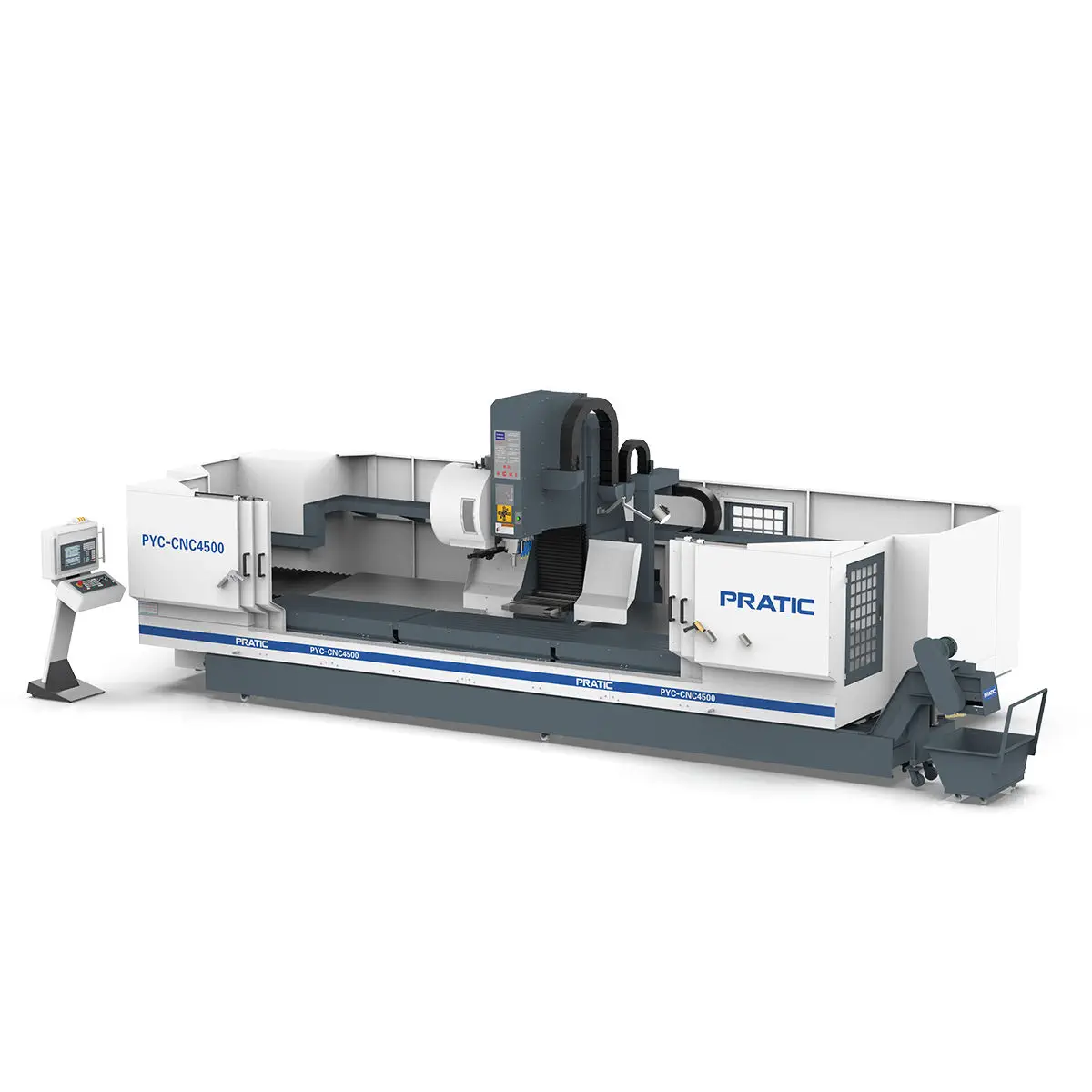

Vertical Machining Center

VMC series II

High rigidity

High seismic resistance

High dynamic response

Retail Price

Market price

Supplier:

Ningbo

China

Weight

Stock surplus

隐藏域元素占位

- Product Description

- Product specifications and models

-

- Brand: HISON

- Commodity name: Vertical Machining Center

- 型号: VMC series II

- 特点01: High rigidity

- 特点02: High seismic resistance

- 特点03: High dynamic response

- 供应商: Ningbo

- 地址: China

All-new second-generation technology VMCⅡ Series

The VMCⅡ series features a fixed A-shaped single-column structure with a moving table. Its base components are highly rigid, and the moving components are lightweight, fully meeting user needs. It can complete milling, boring, drilling, and tapping operations in a single clamping. It comes standard with an 8000rpm belt-driven spindle, and a 1.5:1 reduction ratio increases torque by 50%, suitable for high-speed precision machining of small and medium-sized mechanical parts in industries such as general machinery, automobiles, aerospace, and textile machinery.

Specifications cover VMC760Ⅱ/850Ⅱ/1000Ⅱ/1200Ⅱ

Series Features

High Rigidity

The machine bed and main structure are cast from gray cast iron, providing good rigidity and shock absorption. The bed incorporates internal reinforcing ribs, resulting in a heavy-duty bed structure. High Stability

The cross slide and worktable are both cast from gray cast iron. The cross slide uses an ultra-wide span structure design, effectively increasing machine stability.

High Seismic Resistance

The column adopts a person-shaped structure, and the bottom surface is fixed to the bed through scraping and matching. The column uses a "rice"-shaped reinforcing structure inside, which has good rigidity and seismic resistance. The bottom is designed in an "A" shape, effectively increasing the rigidity of the column and reducing the forward tilt caused by the spindle box.

High Dynamic Response

The three axes use AC servo motors, backlash-free elastic couplings, and direct connection with the ball screw, directly driving the ball screw rotation to achieve the reciprocating motion of each axis, resulting in a fast dynamic response.

Previous Page

Next Page

Product specifications and models

Product Introduction

All-new second-generation technology VMCⅡ Series

The VMCⅡ series features a fixed A-shaped single-column structure with a moving table. Its base components are highly rigid, and the moving components are lightweight, fully meeting user needs. It can complete milling, boring, drilling, and tapping operations in a single clamping. It comes standard with an 8000rpm belt-driven spindle, and a 1.5:1 reduction ratio increases torque by 50%, suitable for high-speed precision machining of small and medium-sized mechanical parts in industries such as general machinery, automobiles, aerospace, and textile machinery.

Specifications cover VMC760Ⅱ/850Ⅱ/1000Ⅱ/1200Ⅱ

Series Features

High Rigidity

The machine bed and main structure are cast from gray cast iron, providing good rigidity and shock absorption. The bed incorporates internal reinforcing ribs, resulting in a heavy-duty bed structure. High Stability

The cross slide and worktable are both cast from gray cast iron. The cross slide uses an ultra-wide span structure design, effectively increasing machine stability.

High Seismic Resistance

The column adopts a person-shaped structure, and the bottom surface is fixed to the bed through scraping and matching. The column uses a "rice"-shaped reinforcing structure inside, which has good rigidity and seismic resistance. The bottom is designed in an "A" shape, effectively increasing the rigidity of the column and reducing the forward tilt caused by the spindle box.

High Dynamic Response

The three axes use AC servo motors, backlash-free elastic couplings, and direct connection with the ball screw, directly driving the ball screw rotation to achieve the reciprocating motion of each axis, resulting in a fast dynamic response.

PDF Product Catalog

Exhibition Hall

The seller will attend the following exhibitions