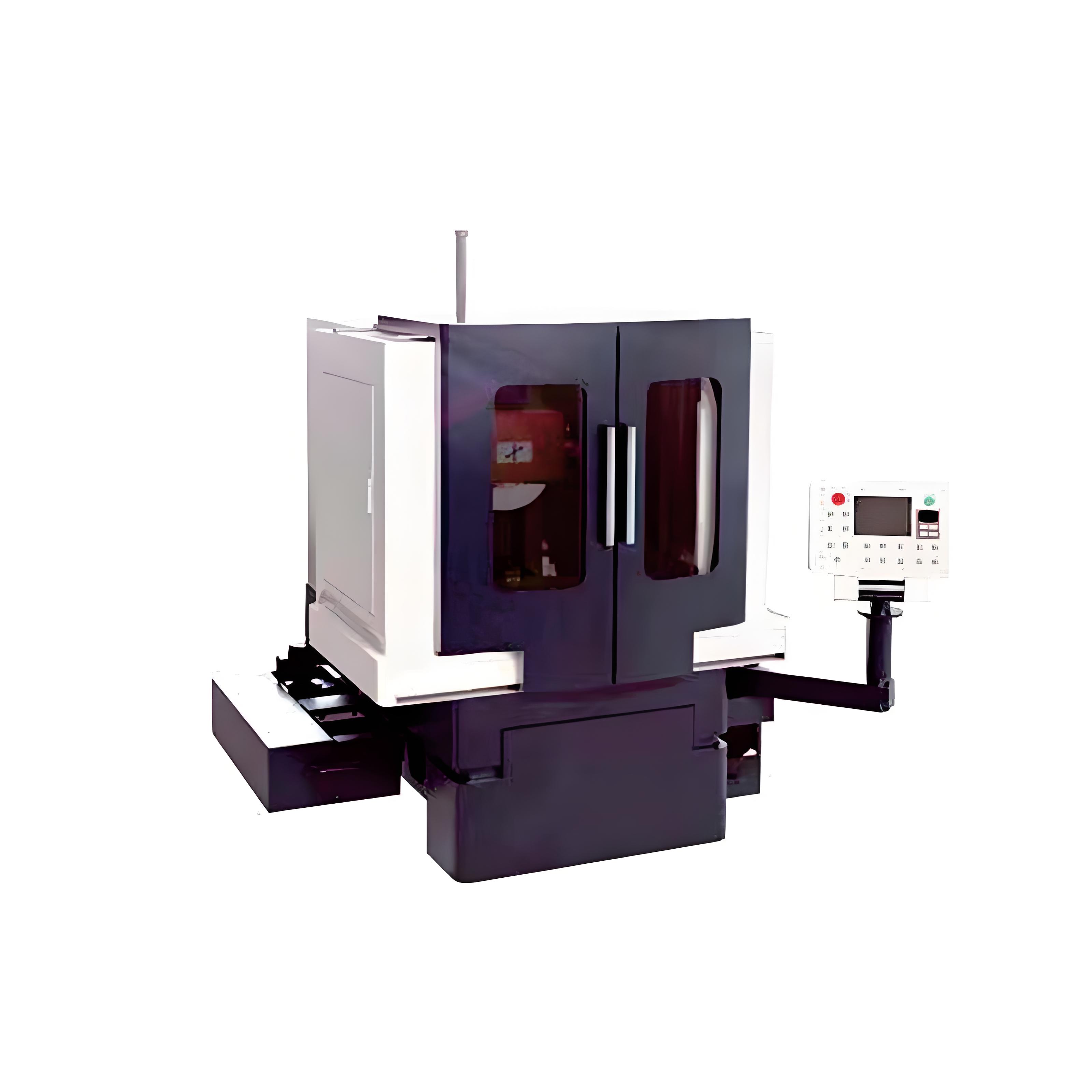

Traveling-column CNC machining center

PCD series

3-axis

vertical

for aluminum

Retail Price

Market price

Supplier:

Changzhou

China

Weight

Stock surplus

隐藏域元素占位

- Product Description

- Product specifications and models

-

- Brand: PRATIC

- Commodity name: Traveling-column CNC machining center

- 型号: PCD series

- 特点01: 3-axis

- 特点02: vertical

- 特点03: for aluminum

- 供应商: Changzhou

- 地址: China

Description

PCD series heavy-duty long-stroke vertical machining center • The machine integrates the function of milling, drilling and tapping • Machining for various lengths of the metal profile, such as aluminum, steel, copper, etc. • Widely used in aerospace, automotive, machinery manufacturing, etc. - Double-arm movable column structure ensures high rigidity and precision - Casting iron bed with strong shock absorption capacity and high physical stability - Top-class numerical control system with high processing stability - Long travel for machining long workpieces or multiple short parts by one clamping Rapid on X-axis: 40 m/min Rapid on Y-axis: 30 m/min Rapid on Z-axis: 20 m/min X/Y/Z cutting feed rate: 15 m/min X/Y/X positioning accuracy: 0.05/0.02/0.01 mm Repeat positioning accuracy: 0.01 mm Machine height: 3600mm Machine covered area: 9500-11500*3150/3700 mm Machine weight: 19000-24000 kg -

Number of axes

3-axi

Spindle orientation

vertical

Structure

traveling-column

Machined material

for aluminum, for steel, for cast iron, for copper, for non-ferrous metals

Spindle mount

BT 40, BT 50, CAT40, SK40, CAT50, SK50

Number of tool stations

16 tools, 20 tools

Associated functions

milling, tapping, drilling

Applications

for the automobile industry, for the aeronautical industry, heavy-duty, for large workpieces, for the mold industry, for aeronautics, for heavy-duty machining, for vehicles

Other characteristics

high-performance, high-productivity, for high-precision cutting, high-rigidity, with tool changer, with linear motor

X travel

4,000 mm, 6,000 mm

(157.48 in, 236.22 in)Y travel

800 mm, 1,200 mm

(31.5 in, 47.24 in)Z travel

600 mm

(23.62 in)Rotational speed

8,000 rpm, 10,000 rpm

(50,265 rad.min-1, 62,832 rad.min-1)Power

15 kW, 17 kW

(20.39 hp, 23.11 hp)Work feed X-axis

15,000 mm/min

(9.84 in/s)Work feed Y-axis

15,000 mm/min

(9.84 in/s)Tool-changing time

6 s

Weight

19,000 kg, 21,000 kg, 22,000 kg, 24,000 kg

(41,887.83 lb, 46,297.08 lb, 48,501.7 lb, 52,910.94 lb)Overall height

3,600 mm, 3,700 mm

(141.7 in, 145.7 in)

Previous Page

Next Page

Product specifications and models

Number of axes

3-axi

Spindle orientation

vertical

Structure

traveling-column

Machined material

for aluminum, for steel, for cast iron, for copper, for non-ferrous metals

Spindle mount

BT 40, BT 50, CAT40, SK40, CAT50, SK50

Number of tool stations

16 tools, 20 tools

Associated functions

milling, tapping, drilling

Applications

for the automobile industry, for the aeronautical industry, heavy-duty, for large workpieces, for the mold industry, for aeronautics, for heavy-duty machining, for vehicles

Other characteristics

high-performance, high-productivity, for high-precision cutting, high-rigidity, with tool changer, with linear motor

X travel

4,000 mm, 6,000 mm

(157.48 in, 236.22 in)Y travel

800 mm, 1,200 mm

(31.5 in, 47.24 in)Z travel

600 mm

(23.62 in)Rotational speed

8,000 rpm, 10,000 rpm

(50,265 rad.min-1, 62,832 rad.min-1)Power

15 kW, 17 kW

(20.39 hp, 23.11 hp)Work feed X-axis

15,000 mm/min

(9.84 in/s)Work feed Y-axis

15,000 mm/min

(9.84 in/s)Tool-changing time

6 s

Weight

19,000 kg, 21,000 kg, 22,000 kg, 24,000 kg

(41,887.83 lb, 46,297.08 lb, 48,501.7 lb, 52,910.94 lb)Overall height

3,600 mm, 3,700 mm

(141.7 in, 145.7 in)

Product Introduction

Description

PDF Product Catalog

Exhibition Hall

The seller will attend the following exhibitions