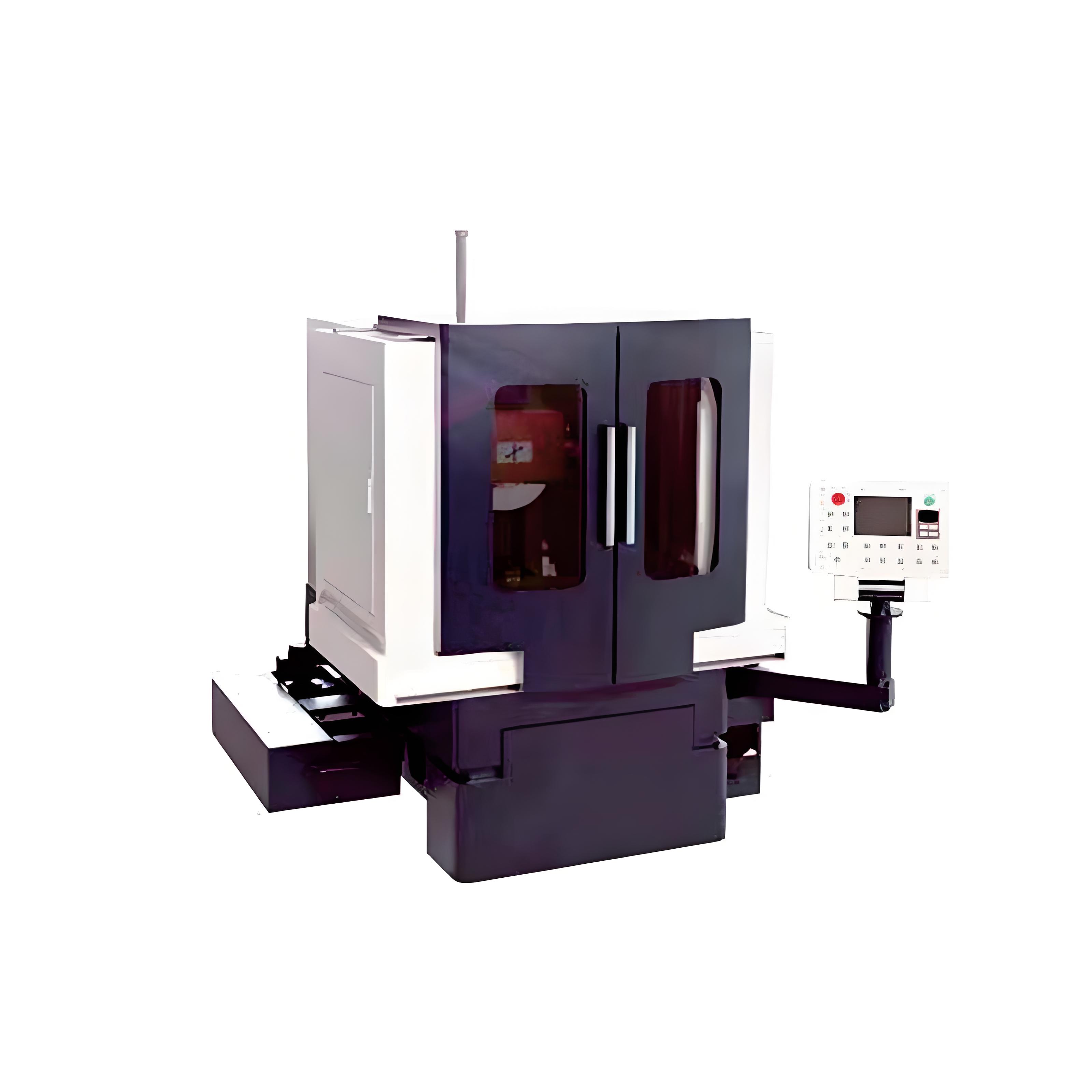

TC series CNC lathe

T C

High rigidity

High stability

High efficiency

Retail Price

Market price

Supplier:

Ningbo

China

Weight

Stock surplus

隐藏域元素占位

- Product Description

- Product specifications and models

-

- Brand: HISON

- Commodity name: TC series CNC lathe

- 型号: T C

- 特点01: High rigidity

- 特点02: High stability

- 特点03: High efficiency

- 供应商: Ningbo

- 地址: China

The front end of the TC series spindle adopts double-row cylindrical roller bearings and high-speed thrust angular contact ball bearings, while the rear end is supported by double-row cylindrical roller bearings; the machine bed is an integral L-shaped casting with 45° inclined rectangular sliding guideways; it features a split tailstock with hydraulically driven sleeve extension; a 12-station hydraulic turret, and a resistance type rare lubrication system. It is widely applicable in various machining industries such as automotive parts, hardware, and energy.

High rigidity, high stability

The integral 45° inclined L-shaped bed has high modal stiffness and high seismic resistance, achieving high rigidity for the lathe.

High precision retention

The machine bed and saddle use hardened guideways, ground after quenching, and the sliding surfaces are covered with wear-resistant soft strips to reduce friction and prevent crawling, ensuring high precision retention.

Spindle thermal balance

The headstock and saddle are installed on the same angular plane, reducing distortion caused by thermal deformation of the headstock and ensuring the spindle's thermal balance.

High efficiency, heavy cuttingThe high-rigidity bed and spindle, large-span hardened guideways, combined with a 12-station hydraulic turret, ensure the machine's high efficiency and heavy cutting capabilities.

Previous Page

Next Page

Product specifications and models

Product Introduction

The front end of the TC series spindle adopts double-row cylindrical roller bearings and high-speed thrust angular contact ball bearings, while the rear end is supported by double-row cylindrical roller bearings; the machine bed is an integral L-shaped casting with 45° inclined rectangular sliding guideways; it features a split tailstock with hydraulically driven sleeve extension; a 12-station hydraulic turret, and a resistance type rare lubrication system. It is widely applicable in various machining industries such as automotive parts, hardware, and energy.

High rigidity, high stability

The integral 45° inclined L-shaped bed has high modal stiffness and high seismic resistance, achieving high rigidity for the lathe.

High precision retention

The machine bed and saddle use hardened guideways, ground after quenching, and the sliding surfaces are covered with wear-resistant soft strips to reduce friction and prevent crawling, ensuring high precision retention.

Spindle thermal balance

The headstock and saddle are installed on the same angular plane, reducing distortion caused by thermal deformation of the headstock and ensuring the spindle's thermal balance.

High efficiency, heavy cutting

The high-rigidity bed and spindle, large-span hardened guideways, combined with a 12-station hydraulic turret, ensure the machine's high efficiency and heavy cutting capabilities.

PDF Product Catalog

Exhibition Hall

The seller will attend the following exhibitions